Quality Assurance & Testing of Our Products

Quality assurance isn’t just a form we fill out; it’s the entire process we follow from the first customer contact we receive until post-installation inspections of the product are completed.

All of our designs are approved by WK licensed Professional Engineers prior to the submittal of our approval drawings to the customer. We take tremendous pride in our technical submittals, and we can honestly say that they are the best in the industry! Our design, fabrication, and testing processes are certified by ISO Certificate.

For projects in the Nuclear sector, we have entered into an alliance with AZZ | NLI and now operate under QA programs that meet or exceed the requirements of ASME NQA-1,10CFR Part 21, ASME III, Canadian Z299 & N285, and several other international standards.

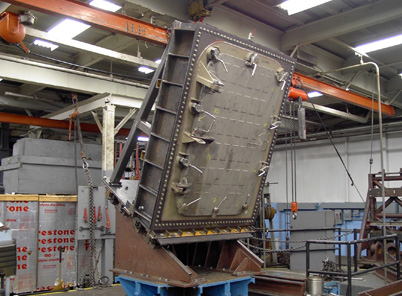

All of our products undergo rigorous factory testing prior to shipment. Each product’s quality assurance plan is based on a combination of our own QA requirements as well as any customer or regulatory body requirement. We invite our customers to visit our shops to witness any of the factory testing.

Additional engineering and testing services are available for critical applications, and include P.E. stamped calculations and drawings, hydrostatic testing, finite element analysis, 3-D modeling, blast/ballistic analysis, material testing, and a full range of NDE processes.

We’ve been doing this since 1939.

Links